Yes, you can laser cut polypropylene, as it works exceptionally well with CO2 laser technology. This material absorbs infrared wavelengths, making it efficient for cutting while minimizing thermal distortion. For optimal results, keep your laser power between 50W and 150W and adjust your cutting speed based on material thickness. You'll benefit from high precision and rapid production times, which are significant advantages of laser cutting. Plus, you can achieve clean edges with less waste. If you're interested in exploring the best practices for laser cutting polypropylene, there's more valuable information to discover.

Key Takeaways

- Yes, polypropylene can be effectively laser cut due to its high infrared absorption compatible with CO2 lasers.

- The cutting process produces clean edges and minimal thermal distortion when settings are properly adjusted.

- Ideal laser power settings for cutting polypropylene range between 50W and 150W for optimal results.

- Laser cutting polypropylene allows for intricate designs and shapes with high precision and speed.

- The air assist feature during cutting helps maintain cleanliness by removing melted particles from the cutting zone.

Material Characteristics

Polypropylene is a versatile material with several key characteristics that make it suitable for various applications. Its density ranges from 0.895 to 0.92 g/cm³, giving it a lightweight yet durable quality. You'll notice it can appear either translucent or opaque, depending on the specific type. The predominant isotactic crystal structure contributes to its high elasticity, allowing it to flex and return to shape effortlessly.

When it comes to thermal properties, polypropylene melts between 130 and 171 degrees Celsius, making it stable under normal conditions. Its low water absorption and hydrophobic nature mean it can resist moisture effectively. Additionally, it displays good chemical stability, showing excellent resistance to many acids and solvents. This makes it a preferred choice in industries that require chemical resistance. Polypropylene's ability to be recycled, although challenging, is an important aspect of its recycling process, which affects its environmental impact.

On the mechanical front, polypropylene boasts good tensile and flexural strength, along with moderate compressive and shear strengths. Its toughness and elasticity make it a reliable choice for applications that require bending and flexing without losing shape.

With high fatigue resistance, this material's smooth surface finish and moderate transmissivity further enhance its appeal in various industries. Overall, polypropylene offers a unique blend of characteristics that cater to diverse needs.

Laser Cutting Process

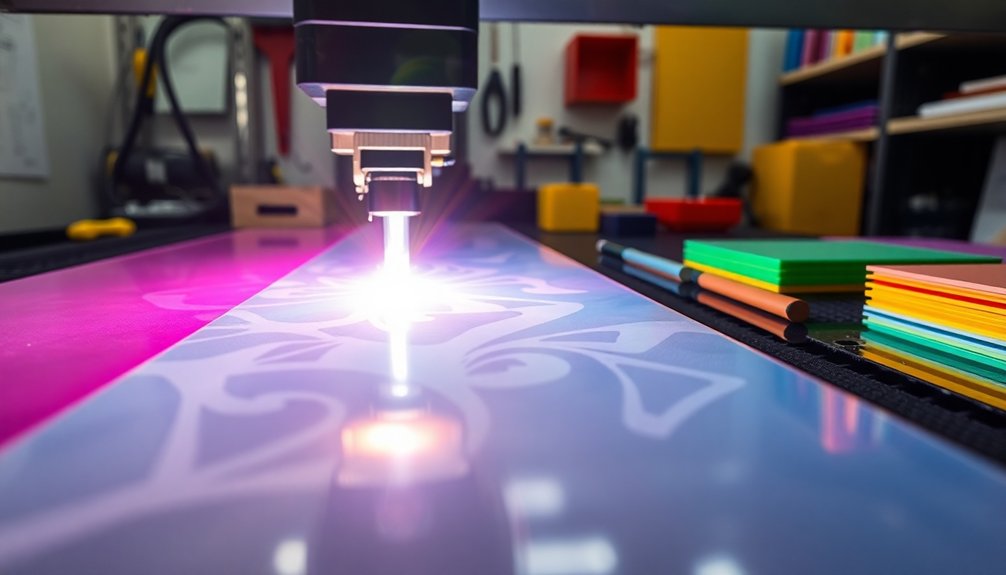

When working with polypropylene, understanding the laser cutting process is key to achieving precise and clean results.

Start by adjusting your laser power settings; for effective cutting, aim for a range between 50W and 150W. If you're using a 40W laser cutter, set the power to 60% to 80% to prevent excessive burning, and fine-tune it between 55% and 65% for optimal edge quality.

Next, adjust your cutting speed. A range of 10-20 mm/sec is ideal for clean cuts, but for thicker materials, slow down to about 1-3 mm/sec. Balancing speed and power helps in reducing heat generation, which can lead to melting.

Focus distance also plays a vital role. Set it to about 50.8 mm (2 inches) above the surface for sharp edges. Additionally, maintaining a low melting point (160-165°C) is crucial to avoid excessive heat buildup during the cutting process.

Lastly, maintain a frequency of 2,500 to 5,000 Hz to ensure smooth cuts and minimize rough edges. By fine-tuning these settings, you'll achieve clean, professional results when laser cutting polypropylene.

Advantages of Laser Cutting

Laser cutting offers numerous advantages that make it an ideal choice for processing materials like polypropylene.

First, you'll benefit from high precision, as the narrow energy beam allows for extremely accurate cuts and intricate designs without significant material distortion. This means you can achieve complex patterns with smooth edges quickly. The process is also suitable for materials with a high tensile strength, which is a crucial factor in selecting the right material for load-bearing applications.

In addition to precision, laser cutting operates at high speed, enabling rapid production times. You can cut through various thicknesses efficiently, reducing overall production time compared to traditional methods. This exceptional processing speed is 10 times faster than bandsaws, enhancing productivity.

Automation also plays a key role, as the process requires minimal operator involvement, lowering labor costs while providing consistent results.

Another advantage is the clean cutting process. With no need for cutting fluids or chemicals, you're ensured minimal thermal damage and reduced risks of contamination. This environmentally friendly approach generates less waste, making it an appealing choice for many.

Finally, laser cutting's material versatility allows you to work with a wide range of substrates, from plastics to metals. This flexibility means you can handle different material properties and thicknesses, making laser cutting a powerful solution for diverse applications.

Applications of Polypropylene

In the packaging industry, polypropylene is favored for its strength and barrier properties, making it ideal for food and personal care products. In automotive applications, its impact resistance and moldability make it a good choice for bumpers and battery trays. The medical field relies on polypropylene for its sterilization capabilities in syringes and vials. Lastly, in industrial uses, its resistance to harsh conditions is invaluable for making chemical tanks and filter inserts. Additionally, its high heat resistance makes polypropylene suitable for applications that require durability under extreme temperatures. Polypropylene's unique properties are also influenced by its manufacturing process, which plays a crucial role in determining its final characteristics and uses.

Special Features of Polypropylene

Over the years, polypropylene has gained recognition for its impressive special features that enhance its usability across various applications. One of its standout characteristics is its thermal properties, with a melting point range between 160 to 166 °C and excellent thermal insulation. Additionally, polypropylene is known for its high melting point, which allows it to withstand elevated temperatures without losing integrity. The material's properties also make it suitable for 3D printing, where temperature management is crucial for preventing warping and ensuring a successful print.

You'll find that polypropylene also boasts remarkable mechanical properties, including high fatigue resistance and elasticity, allowing it to bend and flex without losing shape.

Additionally, if you're considering chemical exposure, polypropylene is highly resistant to diluted acids and bases, making it perfect for containers holding various substances. Its chemical stability ensures it won't degrade under normal conditions, providing peace of mind for storage needs.

When it comes to processing, polypropylene's ability to absorb infrared wavelengths from CO2 lasers makes it an excellent choice for laser cutting. You can expect smooth edges and minimal irregularities, which is crucial for precision projects.

This material isn't just limited to cutting; it can also be welded and drilled with laser technology, offering versatility in fabrication. Overall, polypropylene's unique features make it a reliable option for countless applications in various industries.

Benefits of CO2 Lasers

When it comes to cutting materials like polypropylene, CO2 lasers offer high precision cuts that meet your needs. Their efficient multi-process capability allows you to handle various tasks, from cutting to engraving, all with minimal effort. You'll appreciate how these lasers streamline your workflow while delivering exceptional results. Additionally, these lasers stimulate significant collagen production in skin tissues, making them a versatile tool for both industrial and cosmetic applications.

High Precision Cuts

CO2 lasers offer remarkable advantages for achieving high precision cuts in polypropylene. With their ability to efficiently absorb infrared wavelengths, these lasers ensure clean and accurate results. By using medium-power settings between 50W to 150W, you can create smooth cuts without excessive burning. Additionally, the high precision and flexibility for cutting polypropylene provided by these lasers enhances their effectiveness in various applications.

Here are some key benefits of CO2 lasers for high precision cutting:

- High Energy Absorption: Polypropylene's compatibility with CO2 lasers results in effective cutting.

- Focus Distance Control: Adjusting the focus distance allows for thin kerf widths and sharp edges.

- Air Assist Functionality: This feature helps cool the cutting zone, improving cut quality.

- Minimal Thermal Distortion: The infrared light reduces heat-related damage, ensuring clean edges.

When you focus on power settings between 60% and 80%, you'll achieve optimal results. Thinner sheets can be cut quickly, while thicker materials may require slower speeds.

Efficient Multi-Process Capability

One major advantage of using CO2 lasers is their efficient multi-process capability, making them a go-to choice for various applications.

You'll find that CO2 lasers excel in versatility, easily handling tasks like cutting, drilling, marking, and engraving polypropylene. Their precision machining capabilities allow for complex designs with incredible speed, perfect for industrial processes.

These lasers work exceptionally well with polypropylene due to its efficient absorption of infrared wavelengths, particularly at 10.6 microns. This high energy absorption ensures clean cuts with minimal thermal distortion and burrs, maintaining the quality of your work.

You can optimize power and speed settings to manage polypropylene's low melting point, preventing excessive melting. The ability to control spot size enhances cutting precision, while features like air assist keep the cutting area clean by blowing away melted particles.

With reliable performance and consistent results, CO2 lasers are ideal for various industrial applications. You'll appreciate their multi-functional capabilities, from drilling and perforating to marking and engraving, making them an indispensable tool for any project involving polypropylene.

Frequently Asked Questions

What Thickness of Polypropylene Can Be Laser Cut Effectively?

When considering polypropylene thickness for effective laser cutting, you'll find that materials up to 4mm are commonly suitable. For specific applications, thicknesses like 1.5mm, 2mm, and 3mm work particularly well.

Are There Safety Concerns When Laser Cutting Polypropylene?

Yes, there're safety concerns when laser cutting polypropylene. You should consider toxic fumes like benzene and styrene, manage melting risks, ensure proper ventilation, and follow safety protocols to protect yourself and others.

How Does Polypropylene Compare to Other Materials in Laser Cutting?

When comparing polypropylene to other materials in laser cutting, you'll find it offers smooth cuts, high chemical resistance, and design flexibility. Unlike acrylic, it's less prone to melting, making it a practical choice for intricate shapes.

Can Polypropylene Be Laser Engraved as Well?

Yes, polypropylene can be laser engraved, but it poses challenges. You'll need to use the right settings to avoid melting and warping. Vector engraving is often preferred for clearer, more consistent results.

What Post-Processing Is Needed After Laser Cutting Polypropylene?

After laser cutting polypropylene, you'll need to improve edge quality, minimize melting, ensure clean cuts, and enhance surface finish. Adjust settings, perform test cuts, and use post-processing techniques for optimal results and durability.