Polypropylene is mainly an electrical insulator, with a conductivity that can be as low as 10^-17 S cm^-1. However, it can conduct electricity when modified with specific conductive fillers like carbon black or copper nanowires. By adjusting the filler concentration, you can enhance its conductivity significantly. This versatility makes polypropylene crucial in various applications, especially in electrical insulation for batteries and power systems. If you're curious about how these modifications work or want to explore its practical uses further, there's plenty more to discover about this fascinating material!

Key Takeaways

- Polypropylene is primarily an electrical insulator with conductivity as low as 10^-17 S cm^-1.

- Conductivity can be enhanced by adding conductive fillers like carbon black or copper nanowires.

- The percolation threshold for achieving conductivity in filled polypropylene typically ranges from 0.25 to 0.5 vol%.

- Intrinsically conductive polymers (ICPs) can conduct electricity without fillers, promoting recyclable conductive polypropylene.

- Polypropylene is crucial for electrical insulation in applications such as battery cells and power distribution systems.

Historical Context

Polypropylene, first synthesized in the 1950s by Giulio Natta and Karl Ziegler, marked a significant milestone in polymer chemistry. Initially, researchers focused on its basic properties, exploring its mechanical, electrical, and dielectric performance. Early applications included packaging materials and automotive components, showcasing its toughness, flexibility, and heat resistance. By the 1960s, polypropylene gained widespread industrial use. The production of polypropylene involves various polymerization methods, which have been refined over the years to improve its properties.

Research on polypropylene has evolved over the years. From 2000 to 2004, studies concentrated on its fundamental properties. The next phase, from 2005 to 2011, shifted attention to its thermal properties and modification techniques. Notably, nano-modification techniques have emerged as a leading area of investigation, significantly enhancing the performance characteristics of polypropylene.

More recently, from 2012 to the present, the focus has been on practical applications in the power industry, particularly in developing new insulating materials with high dielectric and temperature resistance.

Key publications during this time have examined the relationship between polypropylene's microstructure and its macroscopic properties. Researchers have also highlighted the potential of polypropylene as a suitable insulation material for power equipment like cables and capacitors.

Electrical Conductivity

Understanding the electrical conductivity of polypropylene is vital for its applications in various industries, particularly in electrical and electronic components. Polypropylene (PP) is primarily an electrically insulating material, boasting conductivity values as low as 10^-17 S cm^-1. Its high electric resistance makes it an excellent choice for insulating electrical parts.

However, you can modify PP's conductivity by incorporating conductive fillers like carbon black or copper nanowires. These additions significantly reduce the electrical resistivity, allowing PP to function as a conductive polymer. The percolation threshold for these fillers generally ranges from 0.25 to 0.5 vol%, depending on their type and structure.

When it comes to measuring conductivity, you'll find it challenging due to PP's high resistivity and the need for specific conditions. The conductivity is also field-dependent, with behaviors varying based on the applied electric field strength. Additionally, the thermal properties of PP, such as its mean thermal conductivity measured at 0.280 W/m·K, can influence its overall performance in electronic applications. Polypropylene's properties, including its chemical resistance, make it a popular choice for various industrial applications.

Keep in mind that ionization is the primary activation process for conduction in PP, rather than diffusion. Overall, understanding these characteristics helps you appreciate the unique electrical behavior of polypropylene in various applications.

Practical Applications

In the realm of practical applications, polypropylene (PP) stands out for its versatility and reliability across various industries. You'll find PP playing a crucial role in electrical insulation, particularly in battery cells and modules, where it provides flame-retardant dielectric protection. Its low-profile design helps prevent surges and arcing in battery packs and power systems, ensuring efficient operation even under high temperatures. Additionally, PolyPro FR® is designed to maintain its form and functionality in high-temperature environments, which is essential for power system equipment.

When it comes to thermal insulation, PP excels in high-temperature applications, making it ideal for power equipment and renewable energy systems. You can also count on PP for effective thermal insulation in home appliances and power distribution systems, reducing heat transfer and enhancing efficiency. The material's overall performance is also influenced by its fatigue resistance, which allows for repeated bending or flexing without failure, making it suitable for a wide range of applications.

With its high chemical and moisture resistance, PP is a go-to material in environments where durability is key. Its exceptional dielectric strength ensures reliable performance in electrical applications, while its mechanical stability allows consistent operation across various conditions.

Whether in telecommunications or electric vehicles, PP's manufacturing flexibility meets the unique requirements of diverse applications, solidifying its place as a reliable choice in modern technology.

Conductive Variants

Several types of conductive polypropylene variants have emerged, significantly expanding its applications in various industries. You can find homopolymer polypropylene made conductive by adding fillers like graphite or carbon black. These conductive fillers enhance the material's electrical properties, allowing it to serve in innovative ways. Polypropylene's tensile strength is also crucial in determining the overall durability of conductive polypropylene variants.

Copolymer polypropylene, especially random and block types, can also gain conductivity through similar means. Intrinsically conductive polymers (ICPs) are another option. These variants can conduct electricity without needing additional fillers, offering unique advantages in specific applications. Additionally, 100% recyclable conductive polypropylene contributes to sustainability efforts while maintaining its electrical properties.

Commercially available options, such as SIMONAVR PP-EL, showcase the potential of conductive homopolymeric polypropylene. When exploring conductive polypropylene, consider that factors like the percolation threshold, filler type, and processing methods can significantly affect conductivity.

The molecular structure, including isotactic polypropylene's stiffness, also plays a role. Additionally, additives and comonomers can alter electrical properties, impacting overall performance.

With these conductive variants, you'll find a range of applications, from electronics and automotive parts to medical devices, making conductive polypropylene a versatile material in today's technological landscape.

Measurement Techniques

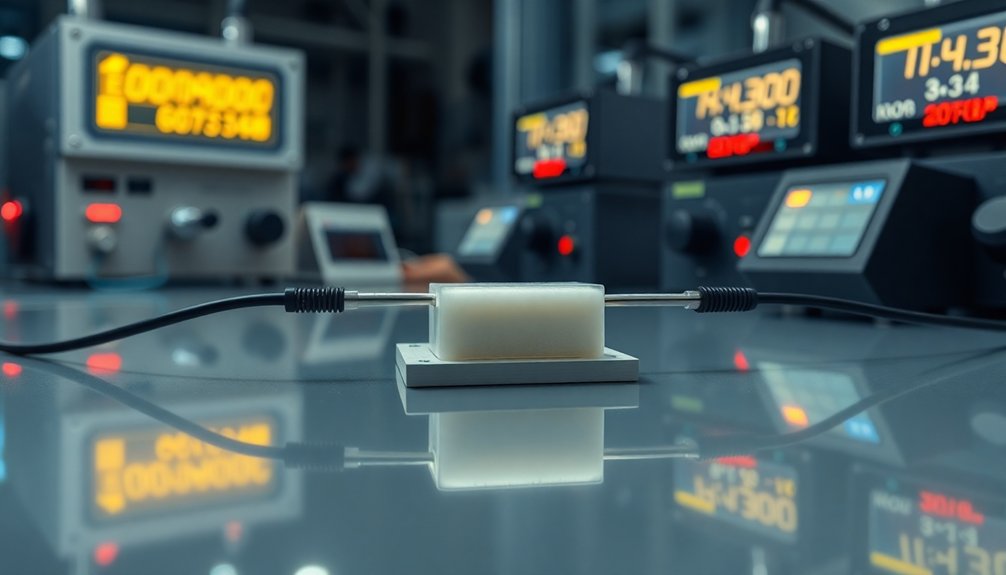

When working with conductive polypropylene, accurately measuring its electrical and thermal properties is vital for assessing performance in various applications.

For electrical conductivity, you can use the J.C. Dubois method, which measures the volumetric conductivity of polypropylene composites filled with carbon black or acetylene black. As you increase the filler concentration, you'll notice conductivity improves, with percolation thresholds at 2.6% for acetylene black and 5.3% for carbon black. This process highlights how conductive polymers can be engineered to enhance conductivity through the addition of fillers. The choice of adhesive is also crucial, and adhesives with high surface energy are often preferred for effective bonding.

To measure thermal conductivity, the Modified Transient Plane Source (MTPS) sensor is your go-to tool. When configured asymmetrically, it provides thermal conductivity values around 0.28 W/m·K at 20°C. For accurate results, ensure you set optimal measurement parameters of 80 seconds and 0.030 W for temperature rise.

You might also consider experimental methods like the Hot Box Test and the DTC-25 Test for assessing thermal conductivity in insulation boards or porous materials.

Using the Measurement Platform Versatile (MP-V) with MTPS ensures you achieve precise and repeatable results, thanks to its ability to eliminate contact resistance.

Frequently Asked Questions

Can Polypropylene Be Used in High-Voltage Applications?

Yes, you can use polypropylene in high-voltage applications. Its high dielectric strength and electrical resistance ensure it withstands extreme conditions, making it a reliable choice for insulation in various electronic components and systems.

What Are the Environmental Impacts of Polypropylene?

You'll find that polypropylene's environmental impacts include greenhouse gas emissions, toxic chemical release, and challenges with recycling. Its persistence in landfills and oceans contributes to pollution, affecting ecosystems and human health in the long run.

How Does Polypropylene Compare to Other Insulating Materials?

When you compare polypropylene to other insulating materials, you'll find it offers excellent chemical resistance and temperature tolerance. While it doesn't conduct electricity well, its durability makes it a strong contender in various applications.

Is Polypropylene Recyclable and Environmentally Friendly?

Yes, polypropylene's recyclable, but its low recycling rate poses environmental challenges. By recycling it, you help reduce landfill waste, conserve resources, and lower greenhouse gas emissions, making it a more environmentally friendly choice overall.

What Are the Safety Concerns When Using Polypropylene?

When using polypropylene, you should be aware of dust explosion hazards, mechanical irritation, thermal burns, unknown toxicity, and the importance of hygiene measures. Always implement safety protocols and use appropriate personal protective equipment to minimize risks.