To screw into plastic lattice, start by pre-drilling holes with a 5/16 inch bit to avoid cracks. Use stainless steel #8 screws, spaced about 24 inches apart for support. Remember to leave a bit of space for expansion—plastic can shift with the temperature. Don't overtighten those screws; allow some wiggle room to prevent warping. It's also smart to opt for pan head screws since they spread out pressure nicely. If you follow these steps, your lattice will hold up well. Stick around, and you'll find even more tips and tricks to make your project a breeze!

Key Takeaways

- Pre-drill holes using a 5/16 inch drill bit to prevent cracking and allow for expansion.

- Use #8 stainless steel sheet metal screws for rust resistance and durability outdoors.

- Space screws every 24 inches for optimal support and stability of the lattice.

- Leave a 1/4 inch gap around all sides to accommodate temperature-induced movement.

- Avoid overtightening screws to prevent warping or splitting of the plastic lattice.

Pre-Drilling Essentials

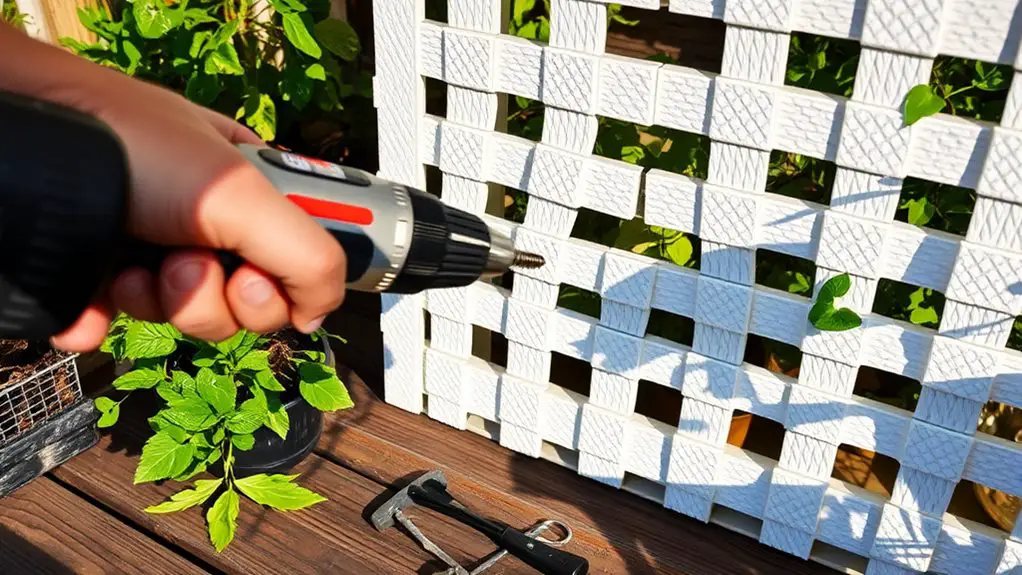

When you're ready to install your plastic lattice, pre-drilling is a must to avoid any cracks or splits. Proper installation overview is essential to ensure a successful project.

First, grab a sharp drill bit that's meant for plastic. You'll want to drill some pre-drilling holes that are slightly larger than the screw diameter—around 5/16 inch works well. This size is perfect because it accommodates the natural expansion and contraction of the lattice.

Next, take your time with the drilling. Keep a consistent speed and pressure; too much heat can melt the plastic and create uneven holes. If you're not careful, you might end up with a mess that'll make your project look sloppy.

Also, remember to create oversized holes. These allow your plastic lattice to move a bit without compromising its integrity, especially when the temperature changes. This way, you won't have to worry about cracks forming later on.

Choosing the Right Screws

Choosing the right screws for your plastic lattice can make all the difference in your installation's success. When working outdoors, you'll want to stick with stainless steel screws. They resist rust and corrosion, which is crucial for keeping your lattice looking great over time.

For most projects, #8 stainless steel sheet metal screws are your best bet. Placing them about 24 inches apart ensures optimal support and durability. Additionally, remember to account for expansion gaps when securing the lattice to prevent warping proper planning and execution.

If you're worried about cracking the lattice, consider using pan head screws. They've a larger surface area, which helps distribute pressure more evenly. This reduces the risk of damaging your plastic lattice during installation.

You might also want to check out washer head or cabinet screws, especially if you prefer a smaller shaft size. These can help minimize the chances of splitting the plastic.

Just remember to avoid regular steel screws at all costs. They'll rust and compromise your installation sooner than you think.

Managing Expansion and Contraction

Managing expansion and contraction is key to a successful plastic lattice installation. As temperatures change, your lattice can expand about 1/16 inch per foot in warm weather. To handle this, you'll need to plan your screw placements carefully.

Here's a quick guide to help you:

| Step | Action | Tip |

|---|---|---|

| 1. Pre-drill holes | Use a 5/16 inch drill bit | This allows for expansion |

| 2. Floating method | Don't tighten screws too much | Let the lattice move freely |

| 3. Temperature changes | Check and adjust screws | Loosen if it bows |

| 4. Regular inspections | Look for cracks or buckling | Keep everything secure |

Effective Cutting Techniques

Before you dive into cutting plastic lattice, it's crucial to have the right tools and techniques to get a clean, smooth edge. Start with a circular saw fitted with a 60-tooth blade. This will help you achieve those neat edges and minimize chipping.

Additionally, ensure that you wear protective gear such as safety glasses and gloves to keep yourself safe during the cutting process. If you want to take it a step further, try running the blade in reverse; it can produce even cleaner cuts and reduce the risk of damaging your vinyl lattice.

Make sure to measure and mark your cuts accurately before you start. This'll help you minimize waste and ensure everything fits just right during installation. If you're looking for a budget-friendly option, an inexpensive plywood blade works well too, but avoid carbide-tipped blades as they can be too aggressive for plastic.

While cutting, proper support is key. Keep the distance between supports to a maximum of 4 feet to prevent sagging or bending.

And don't forget to drill holes for screws if you're planning to attach it later. With these effective cutting techniques, you'll have your plastic lattice ready for installation in no time!

General Installation Guidelines

Installing plastic lattice can be a straightforward task if you follow some general guidelines. First, grab your #8 stainless steel screws for the installation. They're perfect for outdoor use since they won't rust and will hold up against the elements.

When you're ready to start, make sure to pre-drill oversized holes in the lattice. This allows for expansion and contraction, so the holes should be slightly larger than your screw size.

Space your fasteners every 24 inches along the top for solid support. Also, don't forget to leave a 1/4 inch gap on all sides of the lattice. This little bit of wiggle room helps accommodate movement due to temperature changes.

As you screw it in, be cautious not to overtighten. If you do, you risk cracking or warping the plastic, which can really mess up your project.

If you ever need to replace a section, just follow these same steps! With these tips in mind, you'll ensure a successful, durable installation that lasts for seasons to come.

Frequently Asked Questions

What Screws to Use With Plastic Lattice?

When you're fastening plastic lattice, go for #8 stainless steel screws. They're rust-resistant and strong. Pan head screws work best, giving you that extra support. Just avoid regular steel screws; they'll rust and weaken your setup!

How to Secure a Plastic Lattice?

To secure a plastic lattice, pre-drill oversized holes to let it breathe. Use stainless steel screws spaced every two feet, and don't over-tighten them. Check regularly to keep everything stable and in good shape!

What Nails to Use for Plastic Lattice?

When you're nailing plastic lattice, stick to stainless steel nails to avoid rust. Look for pan head or washer head options; they'll hold better and reduce cracking. Just keep those nails about 24 inches apart for stability!

What Is the Best Fastener for Lattice?

For lattice, you want to use stainless steel screws. They resist rust and hold up well outdoors. Try #8 pan head screws spaced 24 inches apart for a secure fit and to avoid damaging your lattice.