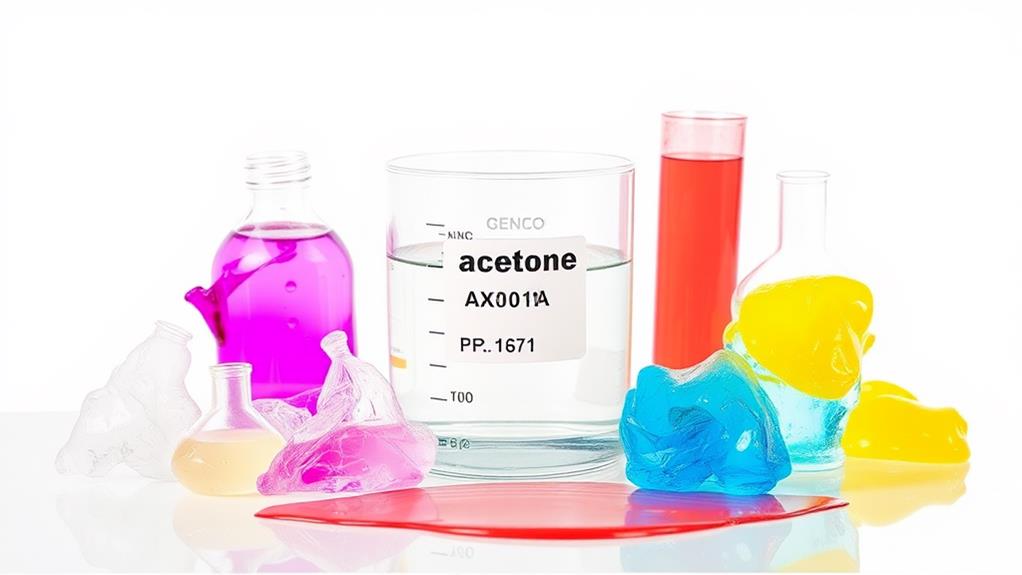

When you're working with acetone, it's essential to know how it interacts with different plastics. Some materials, like polystyrene and polycarbonate, can dissolve quite easily, while others, such as high-density polyethylene, resist its effects remarkably well. Understanding these distinctions can save you from costly mistakes in your projects. But what happens if you mistakenly use a plastic that's not compatible with acetone? The consequences might surprise you. Let's explore the various types of plastics and their reactions to acetone to better equip you for your next endeavor.

Key Takeaways

- Acetone readily dissolves polystyrene and polycarbonate, leading to significant degradation of these plastics.

- PVC and CPVC are highly vulnerable to acetone, risking surface damage and structural failure.

- Cast acrylic can smudge and become damaged upon contact with acetone, losing its clarity.

- Acetal (POM) experiences reduced mechanical properties over time with acetone exposure; caution is advised.

- Fluoropolymers like FEP, PFA, and ETFE exhibit excellent resistance and remain largely unaffected by acetone.

Overview of Acetone and Plastics

When you think about acetone, it's essential to understand how it interacts with different types of plastics. Acetone would dissolve certain plastics, especially those with lower molecular weights or similar chemical structures, like polystyrene and polycarbonate. If you're using acetone, be cautious, as materials such as PVC and polycarbonate are particularly vulnerable to damage.

On the flip side, high-density polyethylene is often chosen for nail polish remover bottles because it has good resistance to acetone. This makes it a safer choice for storage. Fluoropolymers like FEP, PFA, and ETFE exhibit excellent resistance, maintaining their mechanical properties even when exposed to acetone.

However, not all plastics fare well. Acetal and ABS plastics can experience moderate effects from acetone, leading to reduced durability over time.

You should definitely avoid using acetone with PVDF, cast acrylic, and polysulfone, as these materials face a severe risk of dissolution and damage upon exposure. Understanding these interactions will help you make informed choices when using acetone around various plastics, ensuring you preserve the integrity of your materials.

Plastics Rated Excellent

Certain plastics stand out for their exceptional resistance to acetone, making them ideal choices for applications where chemical exposure is a concern.

FEP (Fluorinated Ethylene Propylene) is one such plastic that exhibits minimal reaction with acetone. You'll find that it maintains its mechanical properties even after prolonged exposure.

PFA (Perfluoroalkoxy Alkane) is another excellent option, showcasing negligible impact from contact with acetone.

ETFE (Ethylene Tetrafluoroethylene) is renowned for its strong chemical resistance and remains unaffected by acetone, ensuring durability in challenging environments.

Similarly, ECTFE (Ethylene Chlorotrifluoroethylene) withstands acetone exposure while retaining its structural integrity without significant changes.

Lastly, PCTFE (Polychlorotrifluoroethylene) boasts high resistance to acetone, showing no significant alterations in its properties when faced with this solvent.

These plastics not only resist acetone but also handle harsh chemicals like methylene chloride well.

If you're working on projects that involve these solvents, choosing any of these plastics will provide peace of mind, knowing they won't easily degrade.

Plastics Rated Good

While some plastics excel in resisting acetone, others fall into a "Good" category, offering reasonable performance in environments where acetone exposure might occur.

Plastics like Ulltem and Radell show minor effects when exposed to acetone, making them suitable for occasional contact. However, keep in mind that there are better alternatives available for applications involving frequent interactions with this solvent.

Density polyethylene (PE) is also categorized as having good resistance to acetone. Though it can handle some exposure, it's wise to consider more robust options if acetone contact is a regular part of your application.

While these plastics have a limited risk of dissolution in acetone, exercising caution with prolonged exposure is crucial to ensure material longevity.

If you're planning to use "Good" rated plastics in acetone environments, assess the specific conditions you're working with, such as the concentration and duration of exposure.

These factors will play a significant role in how well your chosen material performs over time. Remember, while these plastics can withstand occasional acetone contact, their performance may degrade with regular use.

Plastics Rated Fair

Facing acetone exposure, some plastics fall into the "Fair" category, indicating they can handle limited interactions but aren't ideal for long-term use. One notable example is acetal (POM). While it can withstand brief encounters with acetone, like nail polish remover, regular contact can lead to significant degradation. Over time, you might notice a decline in its mechanical properties, making acetal unsuitable for prolonged exposure in acetone environments.

Here's a quick overview of the plastics rated Fair:

| Plastic Type | Acetone Resistance |

|---|---|

| Acetal (POM) | Moderate |

If you plan to use acetal, exercise caution. Repeated exposure can deteriorate its performance, and for long-term applications, you should consider alternative materials with better resistance to acetone. This ensures your projects don't compromise on durability due to the effects of nail polish remover or similar substances. Always weigh the pros and cons before choosing the right material for your specific needs.

Plastics Not Recommended

When it comes to selecting plastics for environments where acetone is present, some materials simply aren't up to the task. You'd want to avoid using PVDF (Polyvinylidene Fluoride), as acetone can cause severe damage, leading to structural failure.

Polycarbonate is another risky choice; its chemical structure is too similar to acetone, resulting in significant softening and degradation.

Polysulfone is also vulnerable to acetone, which can lead to potential dissolution and loss of mechanical integrity.

If you're considering cast acrylic, think again—acetone can smear and damage its surface, making it unsuitable for any application involving this solvent.

Lastly, PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) are high-risk options as well; both materials are prone to surface damage and structural failure upon acetone exposure.

In environments where acetone is likely to be present, it's crucial to choose the right plastics. Opting for materials that can withstand acetone will save you from costly repairs and potential hazards down the line.

Stay informed and make the best choices for safety and durability!

Frequently Asked Questions

Which Plastics Does Acetone Dissolve?

When you consider acetone's effects, remember it dissolves polystyrene, polycarbonate, and acrylonitrile butadiene styrene. It can also weaken polyvinyl chloride and acetal, so choose acetone-resistant alternatives like high-density polyethylene or fluoropolymers for safer applications.

What Plastic Container Is Best for Acetone?

When storing acetone, you'll want to use glass, steel, or plastics like polyethylene and polypropylene. These materials won't dissolve, ensuring your acetone remains safe and effective for your needs without any risk of damage.

Does HDPE Dissolve in Acetone?

No, HDPE doesn't dissolve in acetone easily. You can use it for applications involving occasional acetone contact, but remember, prolonged exposure to high concentrations might cause some surface effects. Always exercise caution with solvents.

What Polymers Are Soluble in Acetone?

When you're working with acetone, you'll find it effectively dissolves polystyrene, polycarbonate, and ABS. However, it struggles with polyethylene and polypropylene, so keep those limitations in mind during your projects.