Polypropylene's strength lies in its tensile range of 2,500 to 7,200 psi, making it durable across various applications. With an average tensile strength of around 4,800 psi, it competes well with other plastics. This material can handle stress without breaking, showing excellent resistance to chemical solvents and moderate impact resistance. While it's versatile and cost-effective, it may struggle in extreme temperatures or against certain solvents. If you're curious about how these properties affect its practical uses or limitations, you might find the following insights intriguing.

Key Takeaways

- Polypropylene has an average tensile strength of approximately 4,800 psi, making it strong enough for load-bearing applications.

- The material's tensile strength ranges from 2,500 to 7,200 psi, providing versatility across various uses.

- It exhibits excellent chemical resistance, withstanding solvents and acids without degrading.

- Polypropylene's flexural modulus is 1,265 MPa, indicating good stiffness and resistance under stress.

- While strong, polypropylene's performance may decrease in extreme temperatures and against certain solvents, like chlorinated compounds.

Overview of Polypropylene

Polypropylene, a versatile thermoplastic derived from the propene monomer, stands out as one of the cheapest and most widely used plastics today. This rigid, crystalline thermoplastic boasts impressive mechanical properties, making it suitable for a variety of industrial applications.

With a high melting point of around 327°F (163.8°C), it excels in environments that demand thermal stability.

One of the key features of polypropylene is its chemical resistance, allowing it to withstand exposure to many solvents and chemicals without degrading. This property, combined with its impact resistance, makes it a favorite choice in automotive and aerospace industries.

You'll find that polypropylene can be produced in different forms, including homopolymers, which are stronger and stiffer, and copolymers, which offer more flexibility and durability.

The tensile strength of polypropylene ranges between 2,500 to 7,200 psi, giving it a competitive edge over other plastics like high-density polyethylene (HDPE).

Its versatility means you can rely on it for various applications, whether in furniture manufacturing or packaging.

Additionally, polypropylene is also used in the construction industry, where its durability and resistance to circular economy principles make it a suitable option for certain applications.

Understanding Tensile Strength

When evaluating the strength of materials, understanding tensile strength is crucial, especially for applications involving heavy loads and stress. Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking. For polypropylene, the average tensile strength is about 4,800 psi, allowing it to bear significant loads effectively.

Here are some key points regarding tensile strength in polypropylene:

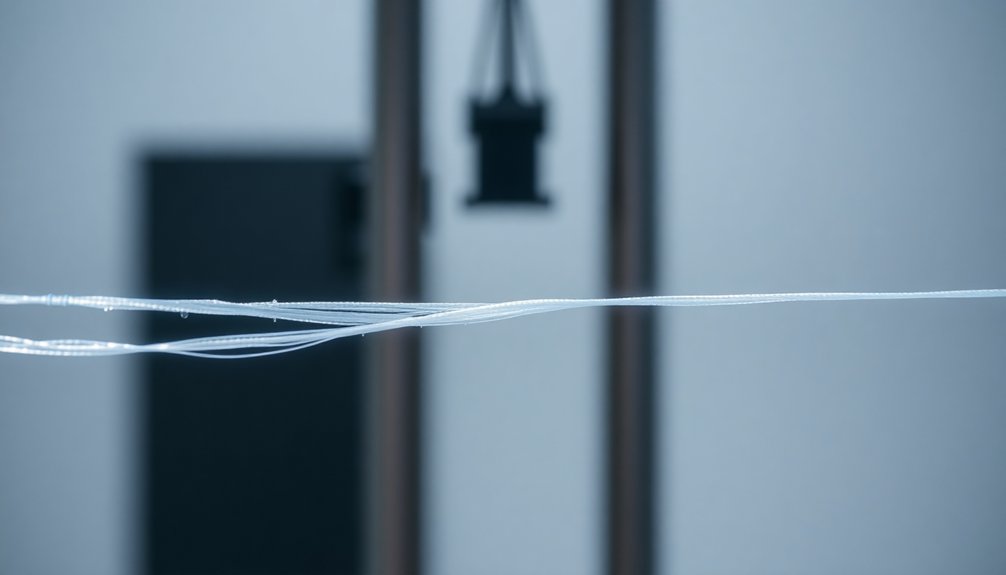

- The tensile strength typically ranges from 2,500 to 7,200 psi, varying by grade and modifications.

- The average elastic modulus of polypropylene is around 1,265 MPa, indicating its stiffness and resistance to deformation under tensile stress.

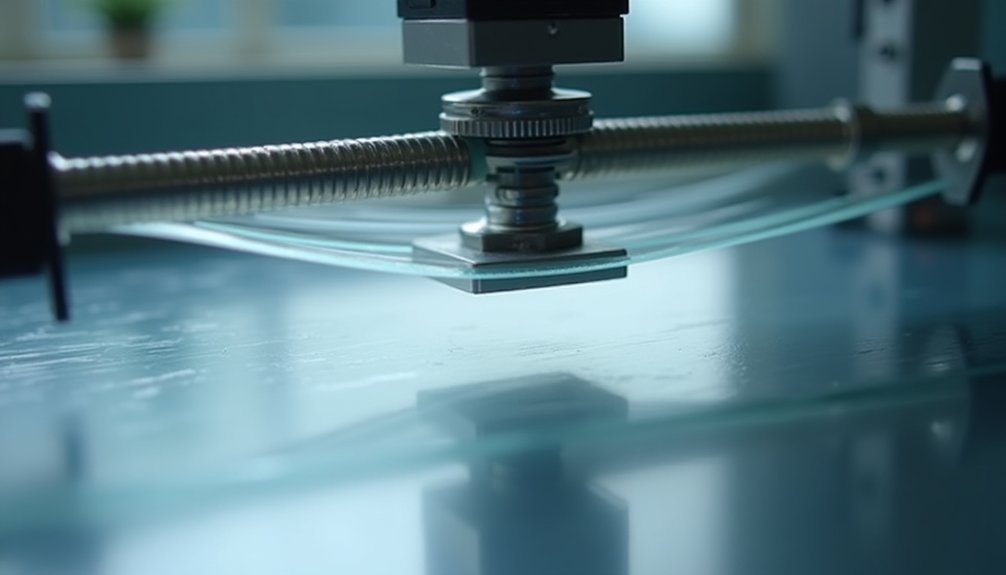

- Tensile testing reveals stress-strain relationships that help assess the mechanical properties of the polypropylene material.

- A temporary drop in stress occurs at just under 3% strain, often due to the testing process.

In the manufacturing industry, understanding these properties helps engineers select the right polypropylene grades for specific applications, ensuring durability and reliability under significant loads.

Grasping tensile strength is essential for maximizing the performance of polypropylene in various products and structures.

Evaluating Material Properties

To effectively evaluate material properties, it's essential to consider various mechanical characteristics that contribute to a material's performance under stress.

Polypropylene, for instance, exhibits a tensile strength ranging from 2,500 to 7,200 psi, making it suitable for diverse load-bearing applications. With an average tensile strength of approximately 4,800 psi, it demonstrates significant load capacity while maintaining its integrity.

The flexural modulus of polypropylene is measured at 1,265 MPa, indicating its stiffness and ability to withstand deformation under stress. When subjected to tensile testing, polypropylene showcases impressive energy absorption, with 0.49 J absorbed, highlighting its impact resistance. This quality makes it particularly valuable in applications where shock absorption is critical.

Additionally, various grades of polypropylene can be modified to enhance their mechanical properties, allowing for tailored specifications that meet specific application needs. This modification can improve both tensile strength and chemical resistance, ensuring the material performs optimally in different environments.

In comparison to other materials, polypropylene's tensile strength is lower than high-density polyethylene (HDPE)'s approximately 4,000 psi, but it still offers versatility and resilience in various applications.

Practical Applications and Benefits

In countless industries, polypropylene stands out for its versatility and reliability. Its impressive tensile strength, ranging from 2,500 to 7,200 psi, makes it a go-to choice for various applications.

You'll find it particularly beneficial in sectors requiring a combination of strength and low weight, such as automotive parts and consumer goods.

Here are some key benefits of polypropylene:

- Chemical Resistance: It withstands exposure to a variety of organic solvents and acids, crucial for packaging and automotive components.

- Impact Resistance: While moderate compared to other plastics, its impact resistance is sufficient for many applications, ensuring protection against minor impacts.

- Moisture Resistance: With a water absorption rate of less than 0.01%, polypropylene excels in environments where moisture is a concern, like medical applications.

- Low Cost: Its affordability makes polypropylene a popular choice across multiple industries without sacrificing quality.

Additionally, its durability also makes it a suitable material for use with electrical components, such as PVC-coated wire, which provides additional protection against abrasion.

Limitations and Considerations

Despite its many advantages, polypropylene has several limitations that you should consider before choosing it for specific applications.

While it boasts a tensile strength ranging from 2500 to 7200 psi, its performance may falter in extreme temperatures due to a melting point of around 327°F (163.8°C). This limitation can restrict its use in high-heat environments.

Additionally, polypropylene's impact resistance is moderate, meaning that softer grades can be susceptible to damage from sharp impacts.

When it comes to chemical resistance, polypropylene performs well against many organic solvents; however, exposure to chlorinated and aromatic solvents can lead to swelling and degradation.

Another critical consideration is its UV resistance. If you're planning on using polypropylene in outdoor applications, be aware that its poor UV resistance can result in material degradation over time when exposed to sunlight.

It's also crucial to consider polypropylene's compatibility with boiling water, as some plastic types, like BPA-Free Plastics, can still pose health risks despite being labeled as safe.

These limitations can significantly influence the performance of polypropylene in various applications.

Therefore, it's essential to assess the specific requirements of your project to ensure that polypropylene is the right choice for your needs.

Frequently Asked Questions

What Is the Tensile Strength of Polypropylene?

The tensile strength of polypropylene generally ranges from 2,500 to 7,200 psi, with an average around 4,800 psi. Depending on the specific grade, it can handle substantial loads effectively in various applications.

Is Polypropylene Very Strong?

Yes, polypropylene's quite strong for many applications. Its tensile strength allows you to handle significant loads, and while it's not the toughest plastic, it offers durability and a good balance of weight and resistance.

What Is the Breaking Strength of Polypropylene?

The breaking strength of polypropylene usually ranges from 2500 to 7200 psi, depending on its grade. If you choose a reinforced version, you might even reach tensile strengths up to 8800 psi for demanding applications.

Does Polypropylene Have Good Impact Resistance?

Yes, polypropylene has moderate impact resistance. While some grades can absorb impacts well, others might deform easily. If you're considering it for high-impact applications, be cautious and choose the right modified grade for better durability.